Founded in 1990, Sharpe Products is an ISO 9001:2015 certified company specializing in industrial and commercial pipe and tube bending, laser cutting, end-forming or other custom fabrication services. In addition, we offer a robust line of architectural handrail fittings and accessories such as brackets, connectors, disks, end-caps, flanges, newel caps and spheres.

Here at Zeman Manufacturing Company we offer a number of services and products including: tube bending, tube end forming, tube assembly, tube cutting, hypodermic tube fabrication, tube coiling, tube swaging, lubricating oil cups, metal tube spacers and custom miniature headers. If you have any specialized requests then give one of our representatives a call today! Please visit our website if you...

With 75+ years of experience, H-P Products, Inc. is a leader in precision tube fabrication. We offer CNC bending up to 8" OD, NC bending up to 10" OD, laser tube cutting, welding, and end-forming to support a wide range of industries. From complex geometries to contract manufacturing, customers rely on us for consistent quality and dependable results.

Diemo Machine Works provides precision machining, custom fabrication, welding, laser cutting, and tube bending services. With meticulous attention to detail and commitment to excellence, we deliver high-quality, custom-engineered solutions that meet the diverse needs of our clients across various industries.

At Erin Industries, Inc., we take great pride in our expertise and capabilities in the field of tube fabrication. With a commitment to precision, reliability, and innovation, we continuously strive to elevate the standards of tube fabrication within the industry. Erin Industries, Inc. is your trusted partner for all your tube fabrication needs, delivering products and services that meet and...

Chardon Metal Products leads the industry in CNC precision machining, tube bending, fabrication, screw machine products, and assembly services. We're proud to offer a diversified portfolio of manufacturing processes to meet customer's needs. Our diversity and problem solving expertise have allowed us to grow and strengthen our position in the marketplace over the past seven decades. Contact us...

At Hafendorfer Machine, Inc., we specialize in tube fabrication services that support precision manufacturing across demanding industrial applications. We work with a wide range of metals and tube sizes, applying tightly controlled processes to ensure dimensional accuracy, structural integrity, and repeatable quality.

At Hafendorfer Machine, Inc., we specialize in tube fabrication services that support precision manufacturing across demanding industrial applications. We work with a wide range of metals and tube sizes, applying tightly controlled processes to ensure dimensional accuracy, structural integrity, and repeatable quality.

More Tube Fabricating Manufacturers

They are usually cylindrical, or round, but the cross-sections, or joinings may vary in shape according to application.

Fabricating is not the forming of tubing from raw materials, but rather includes: annealing, flattening, coating, buffing, sizing, welding, notching, piercing etc existing tubing to meet specific needs. These highly specialized processes require specialized equipment, especially as tubing is often a crucial component of an operation. Tubing is a common feature in many different fields and choosing a particular type includes considering factors such as dimension, performance, opacity, strength.

Consumer items such as steel handrails, bars, bicycle frames, tent frames, displays and furniture use tubing. Industrial and manufacturing industries use hydraulic pipes in applications such as automotive fuel lines, exhaust pipes, hydraulic cylinders, and shell and tube heat exchangers.

Other examples of tubing formed include floor flanges and pipe elbows. Plumbing, engines, machinery, fluid transportation, HVAC processes are all further examples of areas in which tube is an important part and a further reason why precision fabrication is a valuable focus of tube manufacturers.

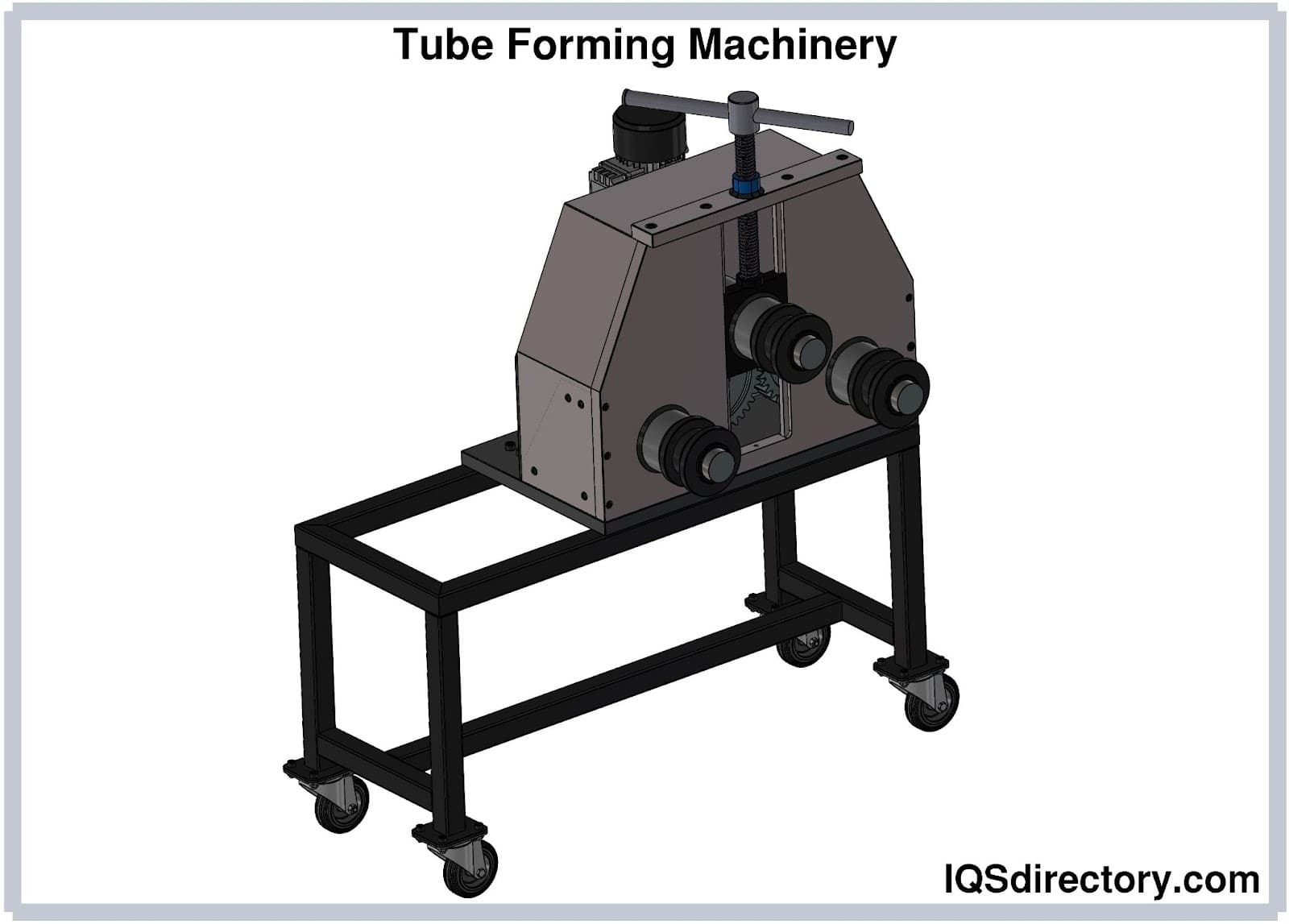

Types of machinery used in the process of tube fabricating use tube benders, mandrels for mandrel bending and tube swaging machines. These all require skilled engineers, operators and may require the assistance of CNC machines and CAD drawings. Tubing is often required to be very specific lengths and dimensions, and therefore using computerized equipment helps to eliminate human error and wastage. Cutting may include notching, punching or drilling.

Flaring and swaging are both cold working processes which expand the diameter of a certain length of tube or pipe, usually to make it capable of connecting with another tube. Hydraulic applications use tubing for a number of processes and it is important for the adjoining tubes to seal tightly to prevent escaping of air or pressure. Tube and pipe bending can be done by hand but is more often done by semi-automated and automated equipment which is faster and more precise than manual bending.

Using a mandrel prevents wrinkles on the interior of the tube around bends and corners and improves the overall quality of flow through the tubing. Tube rolling is the process of producing tubular parts through heat curing materials around a circular mold.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services